has an extensive range of Rubber Sheets. If your requirement is not listed below, we request you to give us your specifications and we will try our best to provide the product as per your satisfaction.

|

NATURAL RUBBER SHEETS (WEAR RESISTANT/SHOT BLASTING RUBBER SHEETS) |

|

Natural rubber sheets or poly-isoprene rubber sheet is the most widely used rubber sheets for almost all general and as well as most dynamic applications.

In some areas, NR is compounded with SBR to increase the temperature resistance of natural rubber sheet.

Colors- Black/white/beige/any other color.

Main Properties:- It offers excellent mechanical properties like high resilience, low compression set, high resistance to cut, tear and abrasion etc. NR also has excellent electrical properties.

Natural rubber sheets also offer resistance to many acids, alkalis and salts.

Main Limitations :- Bad resistance to oil and organic fluid.

Typical applications :- Normally, this type of rubber sheets is used for very stretched range of application but it extensively benefits in the applications like- Chute lining, Shooting/firing range application, rubber lining in shot blasting room, Vibration resistance needs, skirt board sheets, bridge bearing application etc. The NR rubber sheet is also used as food grade sheet if compounded especially.

| Common Name |

Chemical Name |

Nomen-clature |

Hardness Range |

Low temperature resistance |

Heat resistance |

Tensile strength |

Elongation Strength |

| Natural Rubber |

Poly-isoprene |

NR |

Shore A 30 -90 |

-30° C |

Max. Continuous -75° C

Max. intermittent-

105° C |

Up to

200 kg /cm sq. |

Up to 800 % |

|

| |

| Specific Gravity |

Thickness |

Width |

Length |

Surface |

Insertion |

Packing |

Compression Set |

| 1.05-1.8 gm/cm³ |

0.5-6 mm

6-60mm |

1.0/1.2m

1.0/1.2m |

10 m

2.0/2.4m |

Plain (smooth) / fabric marked / patterned. |

Possible –Nylon / cotton / polyester |

Rolls / flats |

Max.50% for 22hrs at 70° C |

|

Nitrile rubber sheets or NBR rubber sheets are generally popular as Oil resistant rubber sheets as these shows very good resistance to petroleum based products. NBR rubber sheets are produced in accordance with BS 2751 standard.

Colors- Black/white/red/any other color.

Main Properties:-NBR rubber sheets offers excellent properties like impermeability to gases, resistance to inorganic chemicals, high resistivity to all petroleum products, high temperature resistance etc.

Main Limitations:-Bad resistance to anti-oxidant agents, chlorines, moderate mechanical strength comparing to NR, moderate weather resistance.

Typical applications: NBR rubber sheets mostly used in gasket industry where gasket comes in contact to petroleum product mainly by manufacturers of Electrical Transformers/oil drilling contractors, sealing against gases etc. This rubber sheet is also used in food applications when especially compounded.

| Common Name |

Chemical Name |

Nomen - clature |

Hardness Range |

Low temperature resistance |

Heat resistance |

Tensile strength |

Elongation Strength |

| Nitrile |

Nitrile Butadine rubber |

NBR |

Shore A 40 -95 |

-20° C |

Max. Continuous -100° C

Max. intermittent-

130° C |

Up to

150 kg /cm sq. |

Up to 400 % |

|

|

| Specific Gravity |

Thickness |

Width |

Length |

Surface |

Insertion |

Packing |

Compression Set |

| 1.32-1.50 gm/cm³ |

0.5-6 mm

6-60mm |

1.0/1.2m

1.0/1.2m |

10 m

2.0/2.4m |

Plain (smooth)/ fabric marked/patterned. |

Possible –Nylon/cotton/polyester |

Rolls/flats |

Max.40% for 22hrs at 70° C |

|

|

Note- 1) Customized dimensions are also available. |

|

|

2)Factory test certificate are available on request. |

|

Abrasion Resistant Rubber Sheet |

|

| Abrasion resistant rubber sheets are compounded from high grade natural rubber to provide the best resistant to cut, wear and abrasion. These type of sheets are widely used in shot blasting industry, rubber linning for material handling equipment or any other crucial application to reduce wear and tear of the parts/ equipments. |

|

| Thickness |

- |

3.0mm to 50mm |

| Width |

- |

Up to 1200mm |

| Length |

- |

Continuous length |

| Color |

- |

Black, White or in desired color |

| Temp. |

- |

-20deg.C to +80deg.C |

| Hardness |

- |

Shore A 40 to 85 |

| Tensile Strength |

- |

≥2Mpa |

| Elongation |

- |

≥180% |

|

|

|

Surface can be smooth or fabric impression. |

|

|

|

| Nitrile sheets with nylon insertion used as diaphragms for oil, LPG & solvent resistant applications These sheets are suitable for wide variety of applications. The purpose of providing insertion is to provide additional strength to the material in order to make it more pressure proof. Generally no. of insertion can be 1 or 2.However more insertions are available on special requests. |

| |

| Thickness |

- |

0.5mm to 50mm |

| Width |

- |

Up to 1200mm |

| Length |

- |

Continuous length |

| Color |

- |

Black, Red or in desired color |

| Temp. |

- |

-30deg.C to + 110deg.C |

| Hardness |

- |

Shore A 40 to 85 |

| Tensile Strength |

- |

5-10Mpa |

| Elongation |

- |

≥200% |

|

ROOFING MEMBRANE

EPDM rubber sheet is special application sheet and proved its suitability in numerous of areas. It has very good weather proof quality that makes the best choice for the outdoor use.

Colors- Black/white/red/any other color.

Main Properties:- EPDM rubber sheet has the properties like high resistivity to steam, water, aging, ozone, oxidation, impermeable to gas, acid proof, good resistance to many chemicals and solvents including many corrosive chemicals. These types of rubber sheets remain stable for long periods of time due to its inert structure.

Main Limitations:- Bad resistance to oil, Moderate compression set etc.

Typical applications:- EPDM rubber sheets is highly used in outdoor and industrial application like roofing membrane, potable drinking water applications, steam sealing applications, weather strips and acid resistant applications and electrical applications due to good electrical strength.

| Common Name |

Chemical Name |

Nomen-clature |

Hardness Range |

Low temperature resistance |

Heat resistance |

Tensile strength |

Elongation Strength |

| EPDM |

Ethylene Propylene Diene monomer |

EPDM |

Shore A 40 -95 |

-45° C |

Max. Continuous -120° C

Max. intermittent-

140° C |

Up to

150 kg /cm sq. |

Up to 400 % |

|

|

| Specific Gravity |

Thickness |

Width |

Length |

Surface |

Insertion |

Packing |

Compression Set |

| 1.2-1.40 gm/cm³ |

0.5-6 mm

6-60mm |

1.0/1.2m

1.0/1.2m |

10 m

2.0/2.4m |

Plain (smooth)/ fabric marked / patterned. |

Possible –Nylon / cotton /polyester |

Rolls / flats |

Max.45% for 22hrs at 70° C |

|

| |

|

Note- 1) Customized dimensions are also available. |

|

|

2)Factory test |

|

SILICONE RUBBER SHEETS

Silicon rubber due to its inert nature is the most preferred choice for Medical, pharmaceutical and food industry.

Colors:- - White/Red.

Main Properties:- -Silicone rubber sheet has the excellent outstanding resistance to oxidation, ozone and weathering. It stays constant at high temperatures and maintains flexibility at even very low temperature.

Main Limitations:- - Bad fuel resistance & Poor physical strength and bad tear and abrasion resistance.

Typical applications:- - Silicones rubber sheets are mainly used in gaskets of pharmaceutical and food industry and areas of extreme high temperature. It also has high application in electrical applications where physical strength is not required.

| Common Name |

Chemical Name |

Nomen-clature |

Hardness Range |

Low temperature resistance |

Heat resistance |

Tensile strength |

Elongation Strength |

| Silicone |

Polysiloxane |

Si |

Shore A 45 -70 |

-65° C |

Max. Continuous -200° C

Max. intermittent-

300° C |

Up to

50 kg /cm sq. |

Up to 200 % |

|

|

| Specific Gravity |

Thickness |

Width |

Length |

Surface |

Insertion |

Packing |

Compression Set |

| 1.15 - 1.25 gm/cm³ |

0.5 - 6 mm

6 - 60mm |

1.0 / 1.2m

1.0 / 1.2m |

2.0 / 2.4m

2.0 / 2.4m |

Plain (smooth)/ fabric marked / patterned. |

Possible – Nylon / cotton / polyester |

Rolls / flats |

Max.45% for 22hrs at 70° C |

|

| |

|

Customized dimensions are also available. |

|

|

Factory test. |

|

|

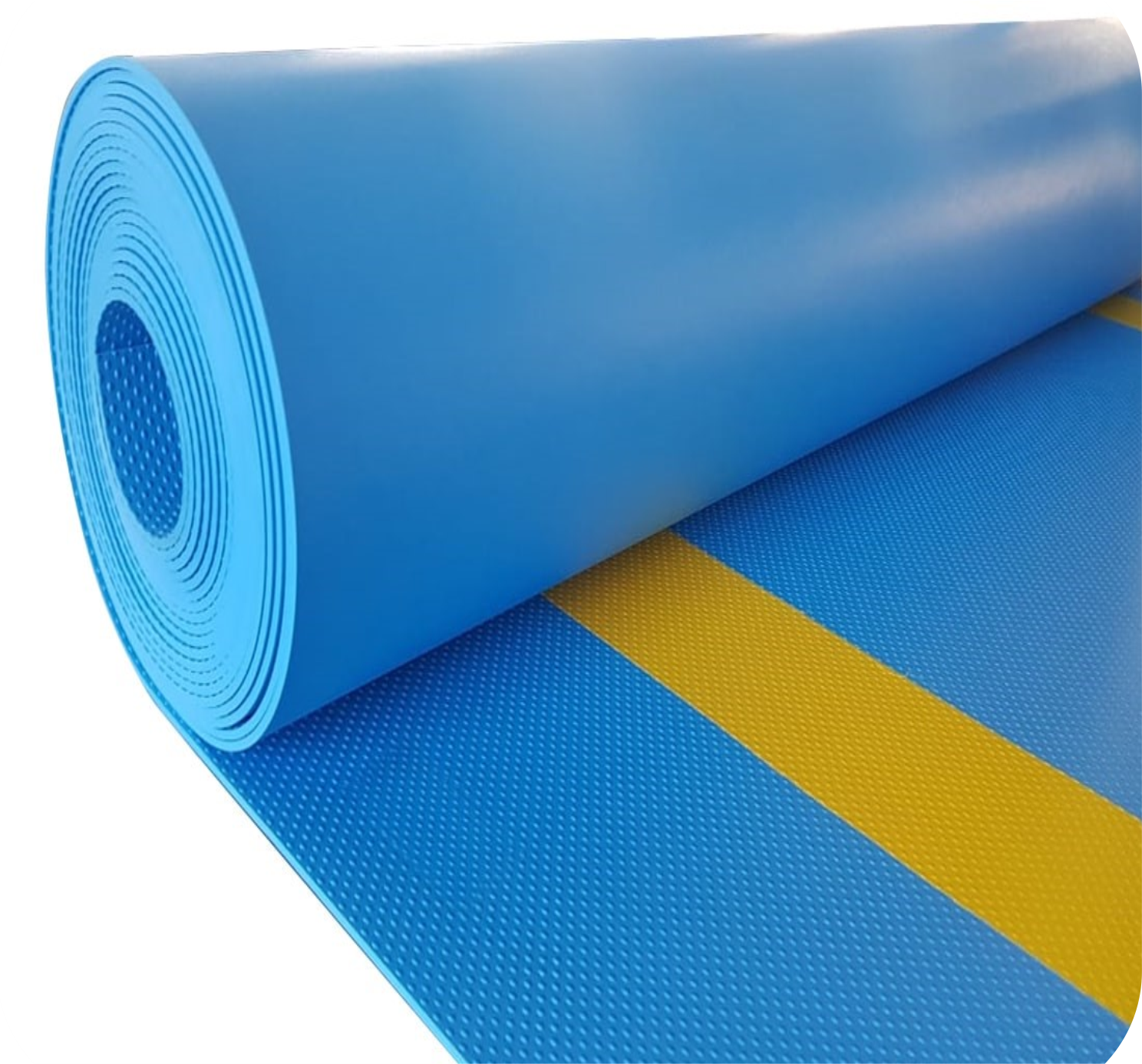

ELECTRICAL INSULATING MATTING / ELECTRICAL SWITCHBOARD MATTING FOR LIVE WORKING (AS PER BS IEC 61111/ EN IEC 61111)

|

|

Electrical insulating matting of rubber covered under IEC 61111 is made of rubber compound suitable for providing the electrical safety to the workmen working around the possible areas of electrical shock. It is specially designed for use in front and rear side of electrical switchboards, High voltage equipments and act as a safeguard equipment from electrical shock due to leakage of current, shot circuit or any other.

Application- In power generation plants, sub-stations, commercial buildings, industrial sheds, marine applications and any other area of electrical shock prone.

Standard- IEC 61111:2009/ BS EN 61111:2009 (BS 921 is withdrawn)

| Item Code |

Class |

Texture on top |

Standard width |

Standard Length |

Standard Thickness |

Max. use Voltage |

Proof Voltage |

Withstand voltage |

| vcl0 |

0 |

Cloth texture |

0.6m / 0.9m / 1.0m / 1.2m |

1m / 2m / 5m / 10m |

3.0mm |

1000 volts |

5000 volts |

10000 |

| vcl1 |

1 |

Cloth texture |

0.6m / 0.9m / 1.0m / 1.2m |

1m / 2m / 5m / 10m |

3.0mm |

7500 volts |

10000 volts |

20000 |

| vcl2 |

2 |

Cloth texture |

0.6m / 0.9m / 1.0m / 1.2m |

1m / 2m / 5m / 10m |

3.0mm / 6.0mm |

17000 volts |

20000 volts |

30000 |

| vcl3 |

3 |

Cloth texture |

0.6m / 0.9m / 1.0m / 1.2m |

1m / 2m / 5m / 10m |

3.0mm / 4.0mm / 6.0mm |

26500 volts |

40000 volts |

40000 |

| vcl4 |

4 |

Cloth texture |

0.6m / 0.9m / 1.0m / 1.2m |

1m / 2m / 5m / 10m |

4.0mm / 6.0mm |

3600 volts |

40000 volts |

50000 |

|

|

| Features: |

|

| 1)Flame retardant. |

|

| 2)Low and extreme low temperature resistance. |

|

| 3)Acid and oil resistance. |

|

| 4)Meets IEC 61111 and BS EN 61111. |

|

| 5)Easy to cut to shape and size as per different laying requirements. |

|

| 6)Anti-slip design. |

|

| 7)Easy to clean. |

|

| 8) Marking- Brand name, trademark, double triangle, Class designation, relevant IEC code, Date of Manufacturing, Batch No. etc. |

| |

|